Houma Armature Works

In-Shop Services We Offer

Repair

Our repair and service shops are ISO 9001 Certified and EASA Certified. Our equipment is calibrated regularly to ensure that our work meets our high standards of service and care. Extensive parts inventory on hand means we are able to complete your job quickly.

In-Shop Balancing

Hard bearing and soft bearing balance to API specs.

- Hard Bearing up to 25,000 lbs.

- Soft Bearing up to 10,000 lbs.

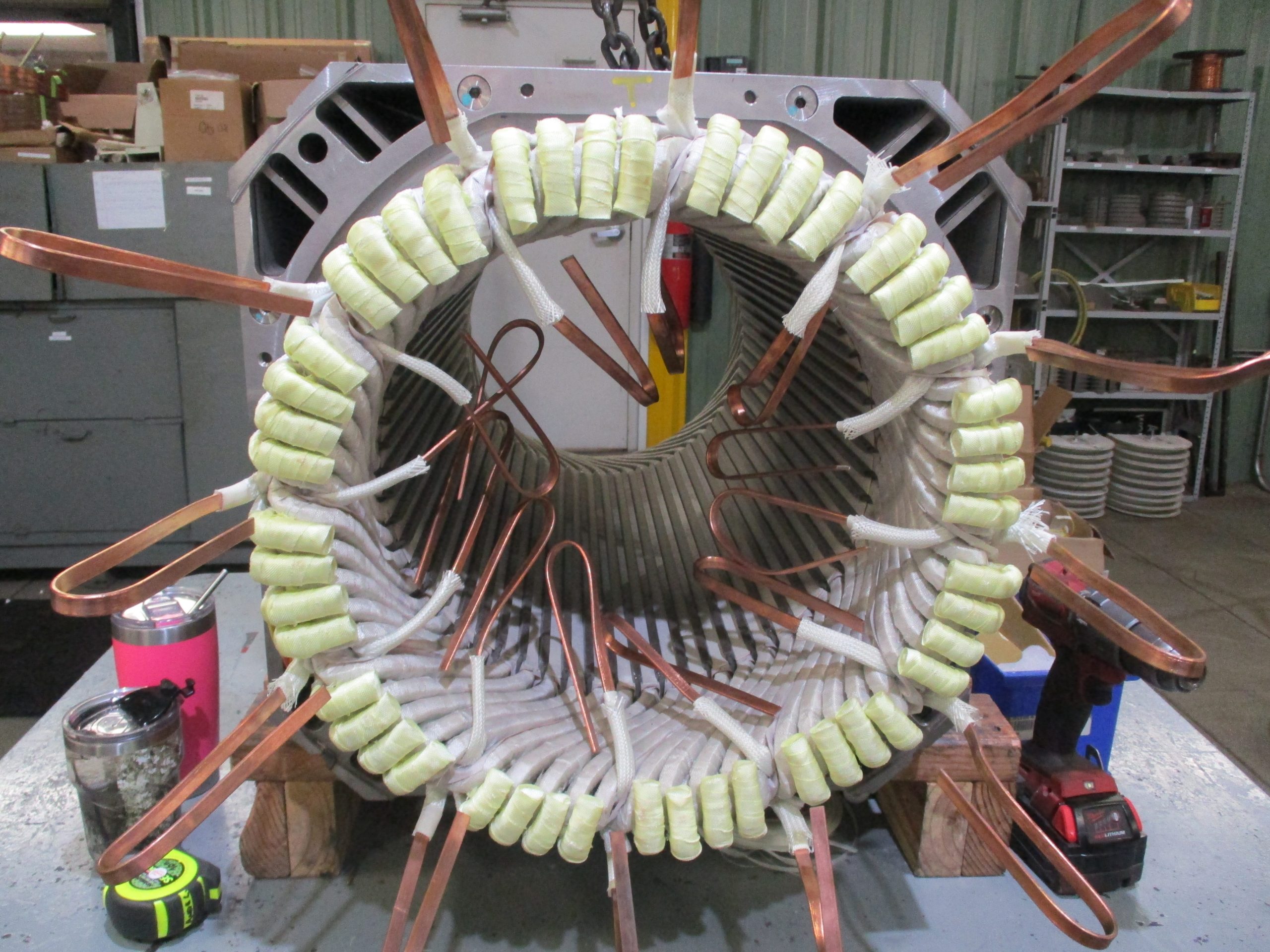

In-Shop Winding

We have a large team of highly trained and expertly skilled winders on staff to perform work quickly while adhering to our high standards of quality and accuracy. Our facilities feature climate-controlled, clean winding rooms to ensure your job is done properly. Our fully automated VPI systems ensures proper insulation integrity.

Fabrication: Welding & Machining

Our facilities have dedicated work areas with both CNC and manual machines for machining to exacting standards, ensuring your job is completed right the first time. Our highly skilled team can do machining of shafts, end frames, seals, and parts, as well as milling on both horizontal and vertical mills. Our well equipped shops can perform metal fabrication on heavy steel, sheet metal, rolling, TIG, MIG, and Stick Welding to manufacture custom components and junction boxes.

Full Load Testing for Motors & Generators

Houma Armature Works load tests each motor or generator we remanufacture in our facilities In order to ensure it will perform to the exact specifications it was originally designed for. The load test is custom designed for each individual motor or generator and fully monitored with a custom data acquisition system. Customers can witness testing either in person or remotely via our web cameras.

- Generators, AC/DC / traction motors

- Complete data acquisition

- Live testing cameras for remote customer view

- Horizontal / vertical load testing

- Full electrical, vibration & infrared testing